The IWM range of boot sole washing and sanitising stations are designed to significantly reduce the introduction of contamination in and out of the production area, through a semi-automated process of mechanical removal and chemical disinfection of the footwear. Furthermore, flexible solutions are available for all types of footwear worn in the production area.

OPERATION

Operators place the boot onto the boot sole washer and presses the start button conveniently positioned on the handle. This activates the rotation of the horizontal brush and spray jets. Gross debris is removed from the soles of the boot/shoe whilst being chemically treated. Water used in this process is then channelled to drain.

FEATURES

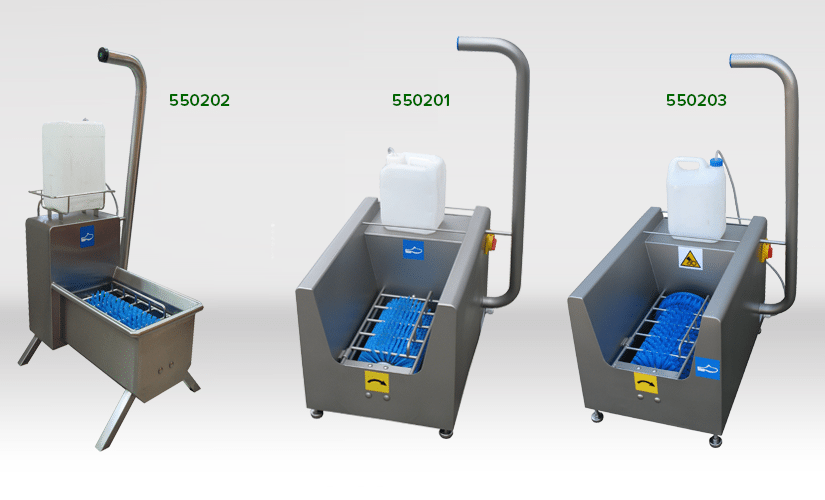

- Overall dimensions: model 550201 560mm long x 650mm wide x 1100mm high

- Dimensions: model 550202 470mm long x 680mm wide x 1100mm high

- Dimensions: model 550203 450mm long x 670mm wide x 1100mm high

- Constructed from fully welded grade 304 Stainless steel, with matt/bead blast finish

- Manual start button

- Supplied complete with automatic chemical dispenser and drum holder

- Horizontal polyamide brush for washing the soles of shoes/boots

- Perforated and dimpled anti-slip surfaces

- No tools required for the removal of panels during cleaning

- Hygienic construction

- The boot sole washer is supported by 4 height adjustable feet

INSTALLATION

The boot sole washing station should be installed at entrance and exit of the production area

BOOT SOLE WASHER UNIT FOR BOOTS/SHOES

- Power consumption in use: 1 x 0,25 kW

- Power supply req: 400V, 50 ÷ 60 Hz

- Water supply: ½” BSP

- Water drainage: 50mm

- Maximal water supply temp: + 50°C

- Number of rotating brushes: 1

| Model | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|

| 550201 | 560 | 650 | 1100 |

| 550202 | 470 | 680 | 1100 |

| 550203 | 450 | 670 | 1100 |