Industrial Washing Machines Ltd are a World Leading Supplier of Beverage Industry Washing Systems

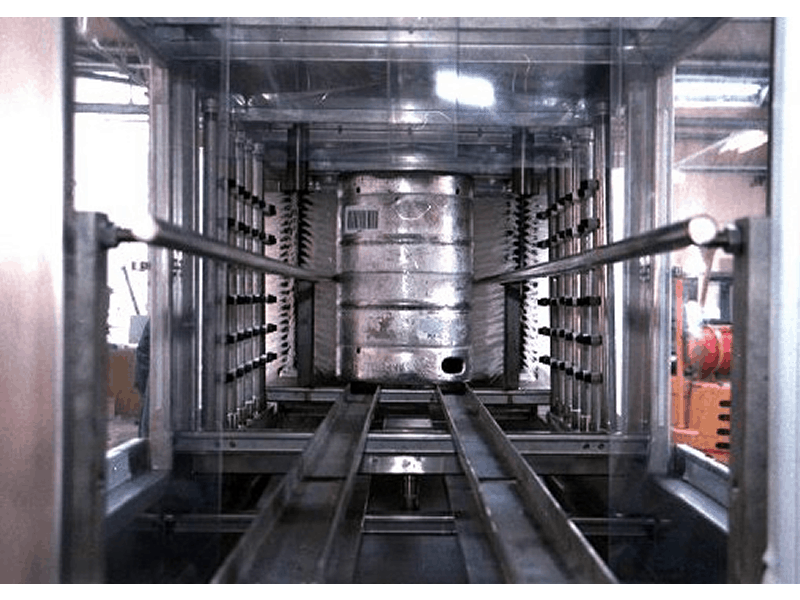

Trends come and go in the UK food and beverage industry. However, there is increasing health and safety compliance. Therefore, there is a requirement to have quality, bespoke solutions, to ensure such rigid requirements are met. As a result, cleaning and washing beverage equipment is ever developing. At Industrial Washing Machine Ltd, we provide a wide range of cleaning machines to choose from for the beverage industry. This includes industrial keg washers and bottle cleaning machines. Additionally, we have prompt adaptability, in terms of lead time and bespoke requirements.

Furthermore, our experience provides us with an edge over our competitors. In addition, we have a range of systems to aid the beverage industry. For instance, industrial crate washers, layer pad (slip sheet) washer and drying systems, keg and pallet washers.

Benefits of IWM Equipment Being:-

- Enhancing production life due to efficient running of the machines, through fewer machine stops and unplanned failures. In the beverage sector, a lot of machinery tends to be “in-line” so reliability is key.

- High level cleaning processes.

- IWM SLA contracts are available for peace of mind. As well as, ensuring continued cleaning with less downtime for years to come, even if managing extremely high throughputs.

- No residue in areas where flow is restricted.

- Increases the service life of the caustic solution – reliable dirt removal.

All equipment is designed and manufactured to individual customer requirements. For instance, we offer single and multi-stage washing facilities from wash-sanitise units to multi-treatment units.

Design Aspects and Optional Extras

Machines available to suit a wide range of throughputs; from small craft suppliers to high capacity fully automated systems. For instance, here are some design aspects and optional extras:

- High Grade Food Stainless steel construction with flexible access panels. As well as, flexible doors and hinges to enable easy hygienic cleaning.

- Conveyor systems are designed to suit the items going to be cleaned.

- Cleaning solution temperature thermostatically controlled.

- Variable output to suit requirements.

- Semi and Auto stack systems.

- High pressure functionality.

- High velocity drying systems.

- Available in single/multi-lane versions.

- Tank heating via steam, gas or electric.

- Detergent dispenser c/w a full range if suitable detergents from IWM.

- Final fresh water rinse from heated, pumped tank or site supply.

- All parts accessible from outside of the machine including filters/nozzles, pumps etc.

- Service Department with SLA’s to suit customer requirements including prompt response times.

Beverage Industry Solutions:

- All types of container washing systems

- Layer pad and top frame washing machines

- Pallet Washers

- Bulk container and stillage washing machines (IBC washers)

Are you looking for an industrial washing machine for bottles or kegs? Get in touch today, our team at Industrial Washing Machined Ltd will be happy to discuss your bottle cleaning or other beverage machine requirements.