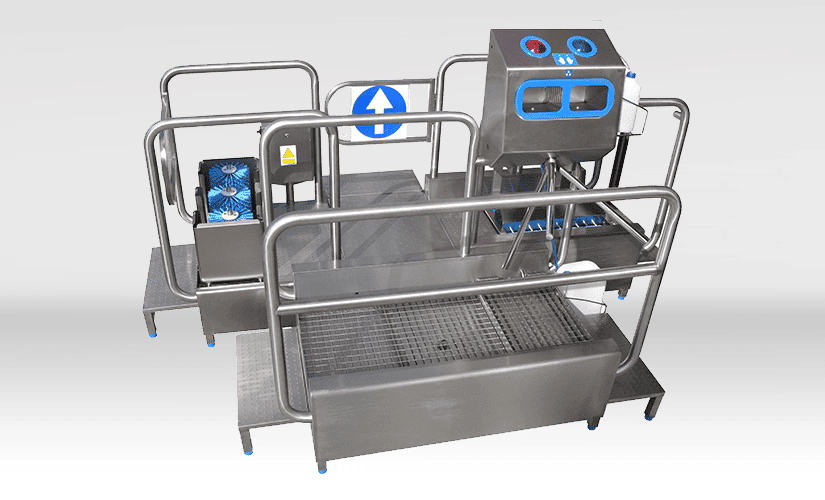

The IWM range of washing, disinfection and sanitising stations are designed specifically for areas where production zones and clean zones of a food production facility meet.

The system controls employee movement, forcing them to perform necessary washing and disinfection steps defined by sanitary regulations. Flexible solutions are available for all types of footwear worn in the production area, including operation on exit to keep changing rooms and corridors free from debris. Stations can be integrated with access control systems.

OPERATION

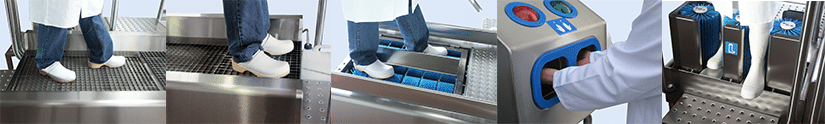

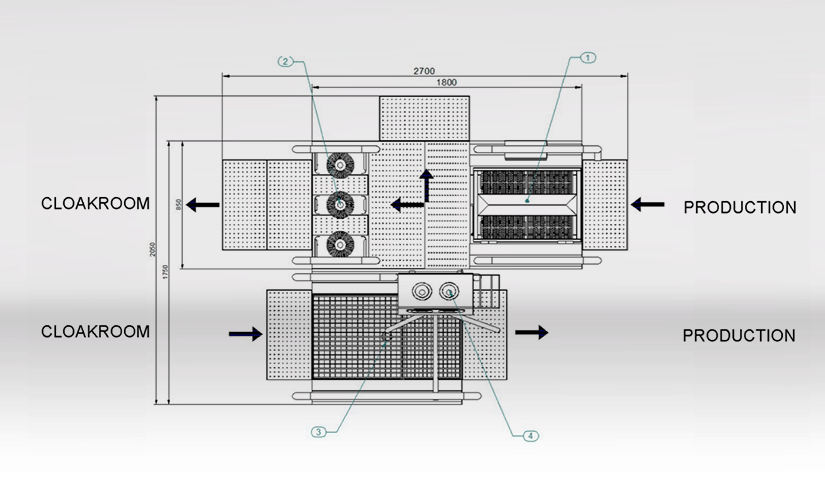

Operators transfer from the clean zone to the production area via the footwear disinfection station (3). Shoe soles and uppers are disinfected by walking through the foot bath, before the operator can pass through the turnstile, both hands must be placed simultaneously in to the hand disinfection unit (4), where a small amount of quick drying disinfection solution is sprayed on the hand, once this process is complete, the turnstile will automatically rotates one 3rd of a turn allowing one operator to pass. Indicator lights turn from red to green during this process.

Operators return from the production area to the changing rooms through a set of integrated automatic footwear washers.

Washer one (1) is designed to wash and chemically treat footwear soles.

Washer two (2) is designed to wash and chemically treat boot uppers only, operators wearing shoes exit the station from the side prior to this.

FEATURES

- Dimensions: 3000mm long x 2000mm

- Constructed from fully welded grade 304 Stainless steel, with matt/bead blast finish

- Water level of foot bath automatically maintained

- Supplied complete with automatic chemical dispensers and drum holder (adjustable)

- Heavy duty s/s gridded floor

- Perforated and dimpled anti-slip surfaces

- No tools required for the removal of panels during cleaning

- Hygienic construction

- Can be integrated with access control systems

- Height adjustable feet

Installation

The washing/disinfection and sanitising station should be installed where its use is obligatory to ensure high levels of hygiene are maintained.

Services required:

- Power supply req: 400V, 50 ÷ 60 Hz

- Water supply: ½” BSP

- Water drainage: 50mm

- Drive: 5 x 25kw (brushes)

- Maximal water supply temp: + 50°C

- Number of rotating brushes: 2 horizontal brushes 3 vertical brushes

| Model | Overall Width (mm) | Width (mm) | Weight (kg) |

|---|---|---|---|

| 552001 | 2700 | 600 | 120.0 |

EXCLUSIONS

All items OR services NOT specifically mentioned in this offer including:

- Packing and delivery to customer

- Import duties OR taxes – If applicable

- Machine installation and commissioning

- Connection to machine mains services – electric, water, drain

- Supply

MANUFACTURING PERIOD

- Typically 6-8 weeks from receipt of order