Comprehensive Guide to Weigh and Scale Pan Washers

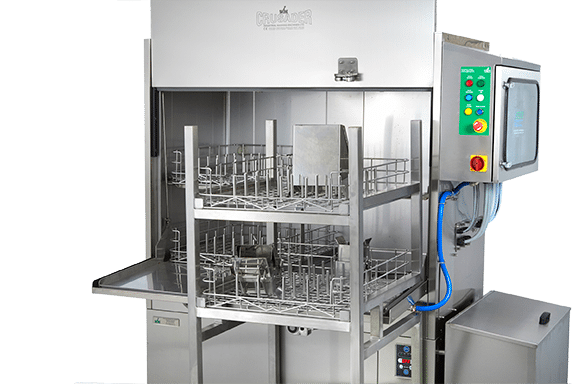

In the fast-paced world of food manufacturing, precision and hygiene are paramount. Weigh and scale pan washers play a crucial role in maintaining these standards by ensuring thorough cleaning and sanitisation of weigh pans and scale pans, which are integral to the accurate weighing of ingredients. Furthermore, Industrial Washing Machines Limited (IWM) offers a new range of weigh and scale pan washers that combine speed, convenience, efficiency, and economy, making them an ideal choice for various sectors within the food manufacturing industry.

Why Use Weigh and Scale Pan Washers?

Weigh and scale pan washers are essential for facilities that require frequent changeovers, such as when introducing a new flavor or after handling common food allergens like nuts, seeds, soy, and dairy products. Industrial washers remove all remnants of previous ingredients completely, preventing cross-contamination and safeguarding against allergen contamination.

Key Benefits of Weigh and Scale Pan Washers:

- Hygiene and Safety: Ensures that all pans are free from food particles and allergens, reducing the risk of cross-contamination.

- Efficiency: Rapid cleaning cycles improve turnaround times and enhance productivity.

- Convenience: Compact designs enable the placement of machines close to production areas, which reduces handling and potential damage to weigh pans.

- Economy: Efficient use of water and detergents lowers operational costs over time.

Features of IWM Weigh and Scale Pan Washers

IWM’s range of weigh and scale pan washers is designed with user needs in mind, following extensive consultation with customers. Here’s a closer look at their features:

- Multiple Models: Available in three models to match specific requirements, capable of cleaning up to 56 weigh/scale pan heads along with accessories.

- Programmable Wash Cycles: The operator can easily select up to seven different wash cycles, with pre-set programs tailored to site-specific needs.

- Advanced Cleaning Technology: Incorporates IWM’s TravelJet system for effective cleaning, with options for plastic or stainless steel jets.

- High-Temperature Rinsing: Ensures sanitisation with a hot water rinse, sufficient to flash dry stainless steel pans.

- Durability and Hygiene: Constructed from stainless steel for longevity and hygienic operation even in hard water environments.

- Accessibility and Maintenance: Designed to eliminate dirt traps and allow easy access to key components for straightforward maintenance.

Installation and Operation

The weigh pan washers are engineered to be as ergonomic and user-friendly as possible. Additionally, smaller models can sit directly on mezzanine floors next to weighing areas to minimise the movement of sensitive equipment, enhancing worker safety and operational efficiency.

Operational Efficiency:

- Loading and Unloading: Manual loading and unloading are straightforward, reducing the risk of injury and speeding up processes.

- Self-Cleaning Cycle: Includes a pre-programmed self-cleaning cycle, reducing manual labor and ensuring the machine is always ready for use.

Applications in Food Manufacturing

Weigh and scale pan washers are versatile and can be used across various food manufacturing settings:

- Bakery: Quick changeovers are essential when dealing with different types of bakery products.

- Meat and Poultry: Ensures thorough removal of raw meat residues, crucial for preventing bacterial contamination.

- Dairy: Effective in handling the stringent hygiene requirements of dairy product manufacturing.

FAQs on Weigh and Scale Pan Washers

What makes IWM weigh and scale pan washers ideal for food manufacturing?

IWM washers, specifically designed to meet the rigorous hygiene standards of the food industry, feature customisable options that adapt to various production requirements.

How does the cleaning process work?

The washers use a combination of high-temperature water and detergents, circulated through precision-engineered jets to ensure complete coverage and effective cleaning. Additionally, this method enhances the removal of stubborn residues, ensuring optimal sanitation.

Are the washers difficult to maintain?

No, IWM designs its machines with ease of maintenance in mind. Components are easily accessible, and the machines include features to minimise dirt accumulation. Furthermore, this design approach significantly reduces downtime and maintenance costs.

Can these washers be customized for specific facility needs?

Absolutely, IWM offers customisation options to ensure that the washers fit the specific operational and spatial requirements of different facilities.

Conclusion

Investing in high-quality weigh and scale pan washers from Industrial Washing Machines Ltd is a wise decision for any food manufacturing facility looking to enhance efficiency, maintain high hygiene standards, and ensure compliance with health regulations. Moreover, with their advanced features, customisable options, and reliable performance, these washers are an invaluable asset in the quest for excellence in food safety and quality.

Explore more about our solutions and how they can benefit your operations. Equip your facility with IWM’s cutting-edge technology and step into the future of efficient.