How Much Does an Industrial Washing Machine Cost?

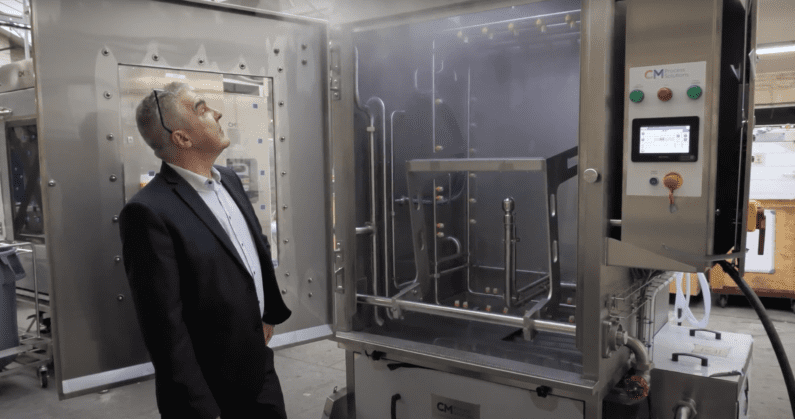

When customers first inquire about IWM’s range of industrial washing machines, the first (or maybe the second) thing they ask is “how much does an industrial washing machine cost?”. Sometimes, we can give a price for an off-the-shelf product, such as a small cabinet utensil washer (from approximately £4,000). However, most of the time the […]